In the world of printing, innovation never stops. From traditional analogue methods like screen and pad printing to cutting-edge digital technologies, the landscape is constantly evolving. As industries continue to adapt to the demands of modern consumers, a new era has dawned. With over 50% of consumers globally preferring goods or services uniquely tailored for them, it's the era of on-demand printing, and the key to its success lies in the harmonious blend of analogue and digital techniques.

A black electronic device with printed customisation

In this article, we'll explore the benefits of using both analogue and digital printing methods, showcasing the unique advantages of each. We'll delve into the latest product from Roland DG, the MO-240 UV flatbed printer, and discover how it perfectly complements traditional techniques to offer a comprehensive, flexible, and high-quality printing solution. This technology is designed to help the shift from mere production to customised production, where products are not only tailored to individual preferences but also aligned with their values and identity. As a result, it fosters a deeper sense of connection and brand loyalty.

The Power of Analogue Printing

Techniques like screen and pad printing have provided businesses with a reliable means of transferring intricate designs onto various surfaces, and they continue to have their place in the modern printing world. Analogue printing techniques are known for their substrate versatility, durability, and cost-effectiveness for long runs. However, analogue methods also come with their own set of limitations. They can be time-consuming, requiring meticulous setup and maintenance. Additionally, they may not be suitable for businesses that need smaller print runs or fast turnarounds, which brings us to the advantages of digital printing.

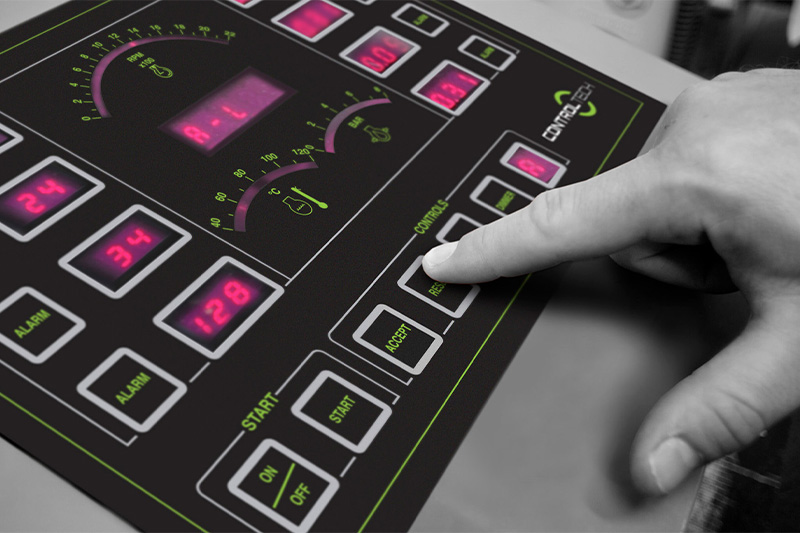

Someone pressing a button on a device on a customised electronics board

The Rise of Digital UV Flatbed Printing

Digital UV flatbed printing has revolutionised the printing industry in recent years. Its ability to meet the demands of the modern market, with its need for personalisation, short print runs, and fast turnarounds, is unmatched. Here's why digital printing is a game-changer:

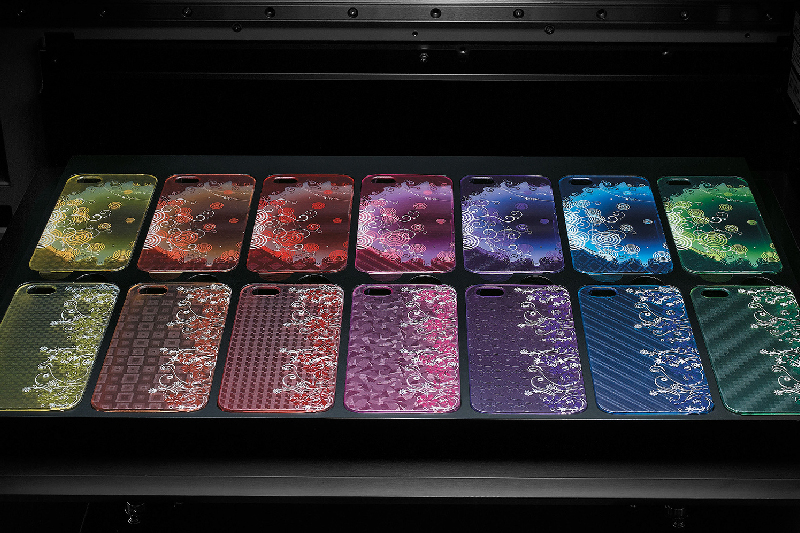

Multiple phone cases printed on a jig

- On-demand Printing: One of the most significant benefits of digital printing is its ability to produce items on demand. This means no excess inventory, reduced waste, and the capability to respond swiftly to market demands. It's the eco-friendly and cost-effective solution of the future.

- Endless Customisation: Digital flatbed printing enables limitless customisation. Whether it's personalised labels, promotional products, or unique designs, businesses can cater to individual customer preferences without the need for costly set-up changes.

- Reduced Set-up Time: Unlike analogue methods, digital flatbed UV printing requires minimal set-up time. This results in quicker job turnarounds and cost savings, making it the perfect choice for smaller print runs and tight deadlines.

- Consistent Quality: The precision and accuracy of digital printing ensure consistent quality across every print. This is especially crucial for businesses that demand uniformity in their branding and product quality.

- Infinite Design Possibilities: Digital printing unlocks a world of design possibilities. With the ability to print full-colour graphics, intricate details, and even photographs, businesses can create visually stunning products that stand out in the market.

- Highly individualised: Each product is entirely unique to the specific customer, catering to their preferences, sizing, and even behaviour.

- Enhanced customer engagement: Personalisation fosters a deeper connection between businesses and customers, as they co-create products based on individual desires.

- Full control: Digital print gives businesses full control over their print workflow, from overall consistency of quality to competitive delivery times and a quick return on investment.

- Specialist UV Ink: UV ink offers superior scratch and chemical resistance, with reliable outdoor durability. Instantaneous curing allows for rapid productivity, ideal for applications such as industrial customisation.

A Perfect Partnership: The Roland DG MO-240 UV Flatbed Printer

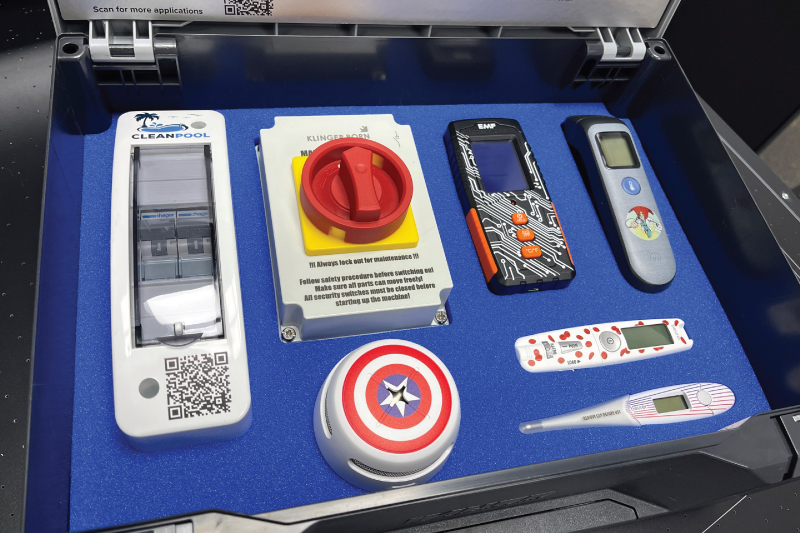

A case containing customised electronics

Recognising the benefits of both analogue and digital printing methods, Roland DG has developed the VersaOBJECT MO-240, an industrial digital flatbed UV printer that complements traditional techniques seamlessly. This innovative solution takes the best of both worlds and combines them to provide businesses with a flexible, high-quality printing solution. With the MO-240 you can:

- Print on Virtually Any Surface: Just like traditional analogue methods, digital flatbed printing can print on an extensive range of substrates, including plastics, metals, and glass. This ensures versatility in the materials you can work with and the products you can offer.

- Vibrant Full-colour Printing: Harness the power of digital printing with this printer's capability to produce vibrant, full-colour prints. The UV-cured inks create eye-catching graphics and visuals that pop off the product.

- Variable Data Printing: This printer allows for variable data printing, enabling you to personalise each item with ease. Whether you need to print individual names, unique QR codes, or sequential numbers, the Roland DG printer has you covered.

- Quick Turnarounds: Say goodbye to lengthy set-up times. The MO-240 is designed for rapid job changes, making it ideal for on-demand printing and short print runs.

- Special Effects and Finishes: Just like analogue methods, this digital printer supports special effects and finishes. You can add metallic effects, spot varnishes, or simulated embossing to create products that stand out in the market.

- High Quality and Consistency: Benefit from the precision of digital printing, ensuring high-quality and consistent results across every print. Your brand will maintain a professional and uniform appearance, no matter the volume of products.

- Eco-friendly UV Printing: The UV-cured inks used by this printer are environmentally friendly. They don't emit harmful volatile organic compounds (VOCs), making them a conscientious choice for modern businesses.

A Dynamic Duo: Analogue and Digital Together

Water drops on a blue surface printed with gloss ink

The VersaOBJECT MO-240 provides the perfect bridge between analogue and digital printing. You can have the best of both worlds. Here's how the combination of analogue and digital techniques can benefit your business:

- Cost-efficiency: Analogue methods shine when it comes to large print runs, offering cost-efficient solutions. By incorporating digital printing for small and medium runs, you can optimise your costs while ensuring your customers receive exactly what they want.

- Reduced Lead Times: Rapid job changes and quick turnarounds are the hallmarks of digital printing. By using analogue methods for your bulk production and digital for customised orders, you can significantly reduce lead times and meet tight deadlines.

-

Unlimited Creativity: Analogue methods provide unique special effects and finishes, while digital printing offers endless design possibilities. Combining both techniques allows your business to offer truly remarkable products with superior design and decoration options.

-

Environmental Responsibility: The eco-friendly UV printing technology of the MO-240 aligns perfectly with the growing demand for sustainable products. By integrating this digital solution alongside your analogue processes, you can reduce your environmental footprint.

-

Market Adaptability: In an ever-evolving market, flexibility is key. With both analogue and digital capabilities at your disposal, you can easily adapt to changing customer demands and market trends.

Conclusion: The Future of Printing is Here

As the printing industry evolves, it's clear that the blend of analogue and digital techniques is the way forward. The Roland DG industrial UV digital printer represents a significant step in this evolution, offering businesses the power to combine the versatility and durability of analogue methods with the speed, personalisation, and precision of digital printing.

Whether you're a business owner looking to streamline production, reduce waste, or tap into new markets, Roland DG is your ticket to success. The future of printing is here, and it's all about balance, adaptability, and the power to create unique, high-quality products on demand. With the Roland DG MO-240, you're well-equipped to meet the challenges and opportunities of today and tomorrow.