The In-House Solution

for Milling Custom Titanium Abutments

NEW Abutment Kit AK-1 Mill Custom Titanium Abutments

With a better fit and greater overall esthetics, custom titanium abutments are fast becoming the standard choice for dental implant and lab businesses. The AK-1 Abutment Kit accessory for the DGSHAPE DWX-42W wet mill brings production of custom abutments in-house to make the process faster, more convenient, and more cost-effective.

- A simple yet elegant solution that connects a DWX-42W mill with AK-1 attachments for custom abutment milling

- Eliminates the need and cost of outsourcing with a low cost per unit

- Adds a popular and profitable new wet-milling application for new or existing DWX-42W owners

A Simplified and Flexible Workflow

with the DWX-42W and AK-1 Abutment Kit

The DGSHAPE DWX-42W wet mill is an incredibly adaptable machine for milling popular restoration applications that grow your business and profit. It combines with the AK-1 Abutment Kit that features selected equipment for use with your choice of the industry’s most popular attachments and pre-milled titanium blanks*. The AK-1 delivers an out-of-box solution with all the milling burs, filters and tools you need to set-up your DWX-42W for custom titanium abutments.

*AK-1 attachments and pre-milled titanium blanks sold separately.

Custom Titanium Abutments

Using a kit that includes specially developed accessories and tools, mill custom abutments in just 3-easy-steps with the DWX-42W.

3-Easy-Steps

Switch-Out Tray

Replace the regular tank with the special AK-1 titanium tray.

Connect AK-1 Material Adapter

Connect your choice of AK-1 material adapter* to the work material holder

*Material Adapter Sold Separately

Mill and Complete

Insert and attach the pre-milled titanium block, output your milling job and complete.

Your AK-1 Abutment Kit Includes

(Primary Set)

Three Types of Special-Purpose Milling Burs

Specially engineered burs, compatible with pre-milled blocks from GeoMedi, MEDENTiKA, NT Trading, and DESS.

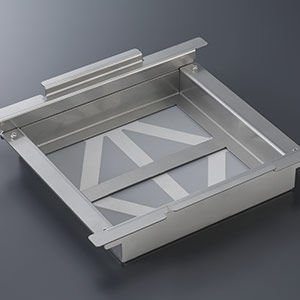

Switch-Out Tray and Two Special-Purpose Filters

Designed specifically for the collection of titanium milling waste, the switch-out tray is supplied with two replacement filters.

Torque Driver

Fix materials to the adapter with the appropriate levels of torque.

Receptacle Tray

Keep your milling materials close-to-hand and your workstation organised.

Hexagonal Wrench

Make adjustments to your milling set-up with the hexagonal wrench.

Material Adapter Attachments

(Sold Separately)

AK-1-GE

Compatible with GeoMedi Geo CMFit® series

AK-1-ME

Compatible with MEDENTiKA PreFace® series

AK-1-NT

Compatible with NT-Trading NT-PREFORM® series

AK-1-DE

Compatible with Dental Smart Solutions (DESS) titanium abutment blanks

A Simply Innovative Solution

that Combines Cost-Effective Production with High-Esthetic Results

No more outsourcing and no more slow delivery times. That’s what the AK-1 Abutment Kit represents for many clinicians and lab technicians. Maximise the profit capabilities of your DWX-42W mill with exceptional cost and workflow benefits— bringing all your custom abutments and revenue in-house.

Additional Features

| Low investment and low cost per unit— purchase a kit with a low price point and you could save many thousands each year on outsourcing costs. | |

| Clinicians and lab technicians have full control over design and materials from start-to-finish— mill both the custom abutment and implant supported restoration in-house. | |

| Produce prosthetics with flexibility for passive fit and correction— custom abutments provide a more precise fit and greater esthetics, especially in the anterior region. |

| Save time, effort while providing a better experience for dental patients— custom abutments require fewer chairside visits and adjustments. | |

| A simple update to the latest version of MillBox Software for your DWX-42W offers you an intuitive CAM solution for custom abutment milling. | |

| Production with your chosen AK-1 material adapter and pre-milled titanium blanks on the DWX-42W is compatible with 3Shape, Exocad, and Dental Wings CAD systems. |

Additional Information

Specifications

| Item | Content | ||||

|---|---|---|---|---|---|

| Applicable model | DWX-42W | ||||

| Supported CAD | 3Shape, exocad, Dental Wings* | ||||

| Supported CAD | MillBox / CIMsystem* | ||||

| Product configuration | AK-1 (Primary set) | Tray with special-purpose filter, three types of special-purpose milling burs, torque screwdriver, receptacle tray, hexagonal wrench, replacement filters, manual | |||

| AK-1-GE / ME / NT / DE (attachment) | 3 types of material attachments GE: GeoMedi; ME: MEDENTiKA; NT: NT-Trading; DE: DESS | ||||

| Productivity | Processing time | 50-80 minutes / tooth (Depends on form) | |||

| Milling bur replacement time | ZTB-150D: 15 hours ZTB-100D: 3 hours ZTB-50D: 8 hours |

||||

| Consumables | ZTB-150D / 100D / 50D | Special-purpose milling burs R1.5mm (Φ3mm), R1.0mm (Φ2mm), R0.5mm (Φ1mm) | |||

Please contact the software manufacturers for latest updates