Shumack Dental & Implants integrates innovation and compassionate care to achieve superior patient outcomes

Shumack Dental & Implants | Australia

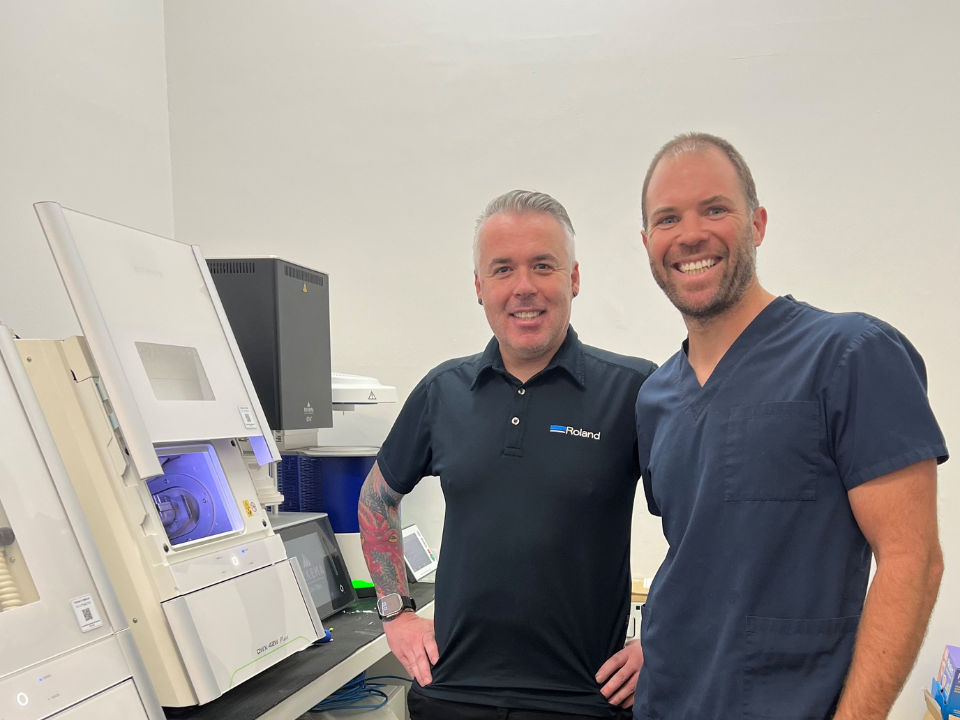

Shumack Dental & Implants has been a cornerstone of dental care in Wagga Wagga, NSW, for over 40 years. Six years ago, Tom Shumack took over the practice, continuing the legacy of high-quality care and expert craftsmanship built by his predecessor during the 35 years prior. Since then, Tom has expanded the practice, broadened its services, and introduced an in-house ceramics lab equipped with cutting-edge technology — ensuring complete control over quality and precision. Personal, compassionate care continues to be their core value.

Roland DG has done an excellent job of dedicating each machine to its specific function. Having two machines also means we can mill multiple restorations simultaneously, improving efficiency and streamlining our production.

Before

- Outsourced ceramic milling to Sydney & Melbourne-based laboratories

- Reliant on Australia Post – long turnaround times, cases were often late or misdirected to the wrong city

After

- Invested in two DGSHAPE mills for specialised wet and dry production to bring all ceramic work in-house

- Able to mill multiple restorations simultaneously, across two machines

- Full control over their processes to deliver high-quality, efficient results while maintaining customised, compassionate care

- Flexibility to make small adjustments in real time, if needed

- Improved efficiency and streamlined production

- Greater patient satisfaction through increased precision, aesthetics and faster turnaround

When Tom Shumack took over the practice in 2019 he inherited a dedicated team, loyal patient base and a clinic with a reputation for high-quality care and skilled craftsmanship.

Since then, Tom’s focus has been on expansion, while maintaining the high standards their patients value and have always received. Tom brought in two new dentists to help grow their services and ensure Shumack Dental & Implants could continue to provide comprehensive, top-quality care as they grew. They also introduced a hygiene program to emphasise preventative care and long-term oral health.

Initially, their ceramic work was outsourced to Sydney and Melbourne-based laboratories, but COVID-related postal delays made that unsustainable. Those operational challenges led Tom to invest in a full in-house ceramic setup, including a DGSHAPE DWX-52D Dry Dental Mill and a DWX-42D Wet Dental Mill. With guidance from experienced clinicians, Shumack Dental can produce anterior veneers (e.max), implant-supported restorations, and more complex bridgework.

Working in conjunction with their two Asiga3D printers ‘virtually running nonstop’, Shumack Dental are now able to ensure precision fit verification before patient appointments and complete their workflow with a zirconia furnace and a vacuum furnace.

Tom says that “adding their in-house ceramics lab, Trios scanners, and CBCT has completely transformed what we can do. Now, we have full control over the process, allowing us to deliver high-quality, efficient results while maintaining the personal, patient-focused care that has always been at the core of our practice.”

Quality control through in-house technology

One of the biggest challenges that prompted their decision to invest in in-house milling was the increasing unreliability of Australia Post, especially during COVID. Cases were arriving late and sometimes ended up in the wrong city which caused major delays and frustration for the team at Shumack Dental and their patients.

Tom explained the situation with examples, “Even though communication with our external labs was excellent, in some instances, teeth shifted due to the extended time between preparation and issue (often 3 weeks!). This resulted in a loose contact, requiring additional adjustments or remakes. In these cases, it was incredibly inefficient to send it all the way back to Sydney just to have a fraction of a millimetre added."

Fortunately, the current state is far better. Tom says “one of the greatest advantages of having our own ceramic lab is the flexibility it provides. If a contact is slightly loose, or if the shade isn’t quite right, or a small adjustment is needed, we can essentially fix it on the spot. A 20-minute turn around while we reglaze a section of a ceramic is much more convenient than a 4-day turnaround.”

Rewards for researching new technology

When selecting a milling system for their practice, Shumack Dental relied on a combination of recommendations and a careful assessment of their needs. Roland DG and DGSHAPE quickly stood out as frontrunners due to their ‘reputation for precision, reliability, and efficiency’. A key influence in Shumack Dental’s decision to choose separate wet and dry mills was a trusted colleague in Queensland who had been using both the Roland DG wet and dry mills for several years. According to Tom “his experience highlighted the consistency and seamless workflow of these machines, particularly the dry mill, which I now consider one of the most reliable machines in our practice.”

Benefits to having dedicated wet and dry DGSHAPE dental mills

One of the deciding factors for Tom was that he wanted “separate wet and dry milling units, rather than a single machine attempting to handle both processes.” Tom remarked “to the best of my knowledge, wet and dry milling requires different technologies, and Roland DG has done an excellent job of dedicating each machine to its specific function. Having two machines also means we can mill multiple restorations simultaneously, improving efficiency and streamlining our production.

Having two machines also means we can mill multiple restorations simultaneously, improving efficiency and streamlining our production.

DGSHAPE quality & support ‘makes a big difference’

The Team at Shumack Dental and Implants couldn’t be happier with their choices saying “the quality and reliability of their DGSHAPE milling units has been excellent. They do exactly what they’re supposed to with a high level of consistency and predictability. Calibration has been easy, and once set up, the workflow runs smoothly every time.”

Tom says “our staff have really enjoyed learning how to use these machines and take pride in their ability to assist in producing high-quality restorations. The whole process has been straightforward, and the accuracy of the results speaks for itself.”

Patients love that we can fabricate their restorations in-house quickly and efficiently. The precision and aesthetics have been impressive, and the fast turnaround has been a huge win for patient satisfaction. Overall, these machines have been a great investment”.

Recommending DGSHAPE

Tom would “absolutely recommend DGSHAPE products” and has done so, to many colleagues, saying “the machines produce outstanding results, but beyond that, the back-end support has been excellent whenever things haven’t gone as expected. Having that reliability makes a big difference.”

Tom remarks “There is an incredible amount of pride in having the capability to fabricate these life-changing restorations within our own practice. The control, efficiency, and quality make DGSHAPE an invaluable investment for any clinic.”

For more information on the products and services offered by Shumack Dental & Implants head to their website.

Learn more about the advanced features of DGSHAPE dental mills here.